WA1ABI, John, in Portsmouth invented a new mode a couple of years back — Christmas Tree to Christmas Tree QRP. Today I had my outside tree wired up to a remote antenna tuner and gave the XMT2XMT mode a try. The photo below shows the remote tuner in the circled area on the bottom left.

The photo below shows the tuner to Christmas Tree light feed — BNC to Banana Plug to Alligator Clips to the plug end of the lights. The green extension cord is disconnected but the U Ground pin can be used as an earth ground if needed.

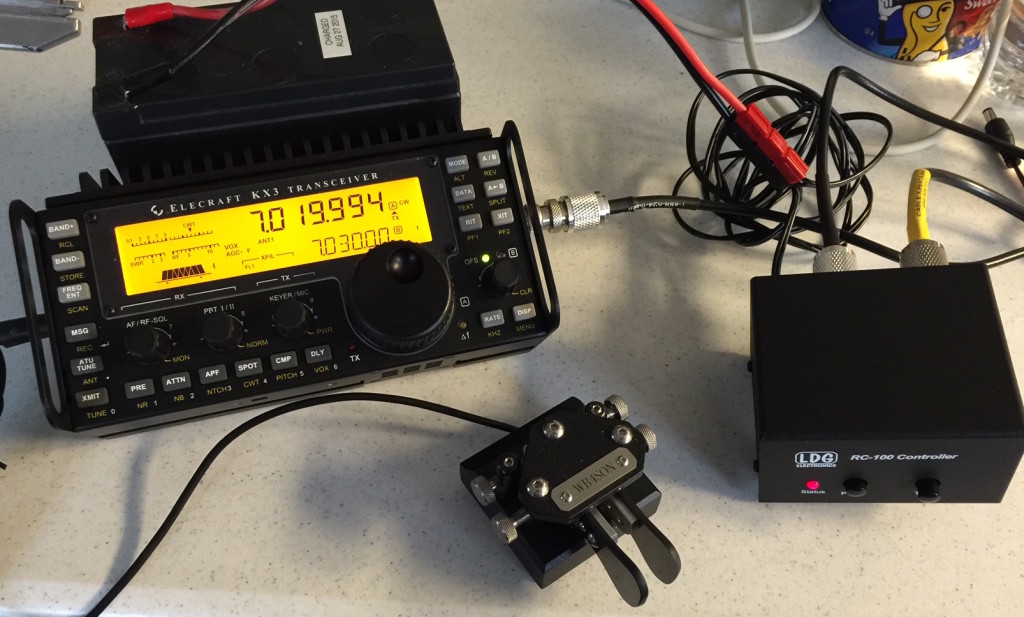

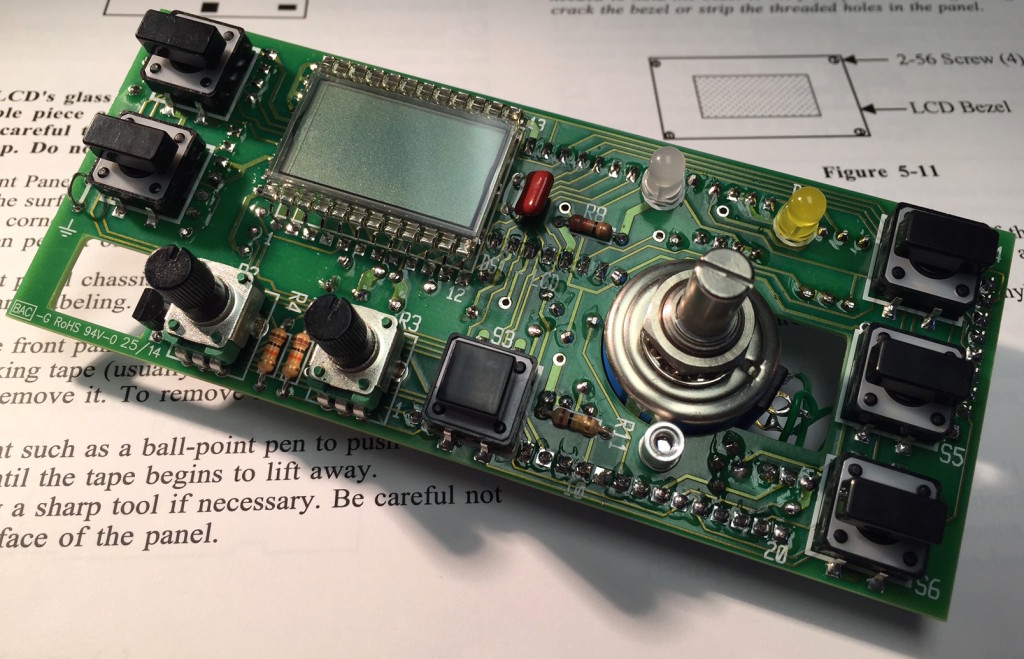

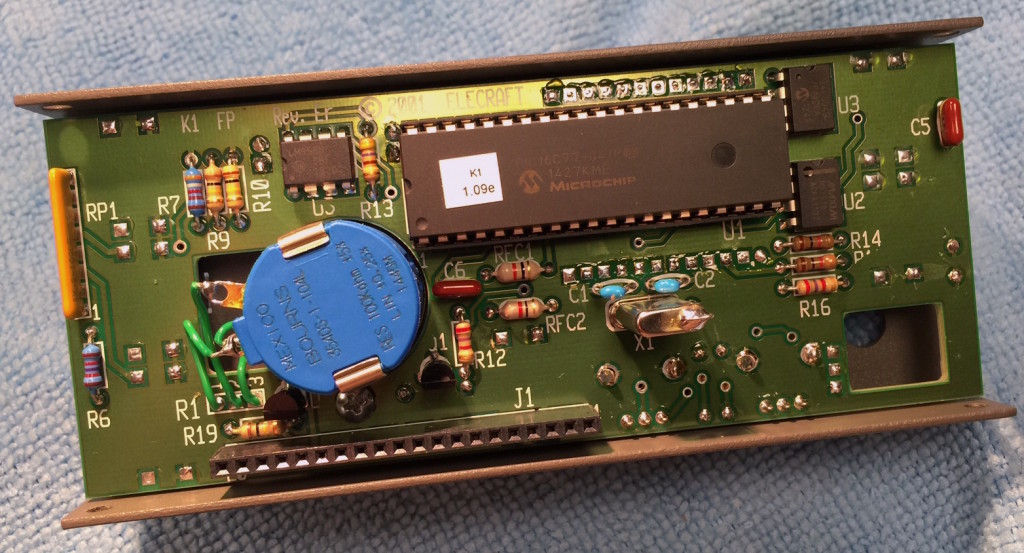

And, of course, my trusty KX3 running the show (LDG Remote Tuner box on the right — note I didn’t want to waste power in the feedline by using the tuner in the KX3)

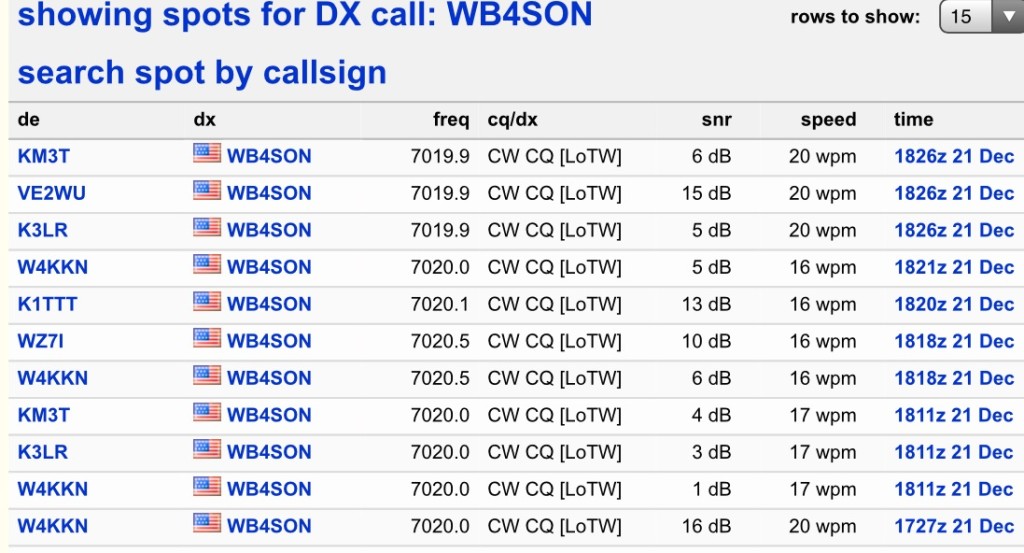

While I wasn’t able to raise WA1ABI, or Bruce NJ3K, I heard them both, and the RBN was hearing me.

The oldest RBN was with feedline across prongs of lights. Newer entries were with hot lead of feedline onto one wire of lights, and the shield to AC Power Ground via extension cord.

Here is an audio recording of Bruce and John in QSO. All of us were running KX3s and using Christmas Trees for antennas.