It’s hard to beat fall in New England. Beautiful colors, amazing apples (cider, hard and soft, plus donuts!). It means all the busy summertime activities are fading away, and being replaced with more leisurely ones. In my case, that means fall & winter construction projects.

I was involved with an event sponsored by my radio club (Newport County Radio Club), that we call “Hands-on Radio”. Unlike a formal club meeting, this gives our members (and guests from the public) a chance to do things in a informal setting with mentors available to coach. About a month ago the topic was soldering skills, and I was one of the mentors.

I was surprised at the range of soldering gear brought by the students, ranging from fairly new to ancient. I saw solder that had to be 0.125″ in diameter, and so oxidized over decades(?) that it was dull grey. In fact, in several cases, I was concerned that folks were using acid core solder, as the rosin was pitch black. Believe it or not, solder has an expiration date — 3 years from date of manufacture. Of course you can use it beyond that date, but the effectiveness of the rosin as well as the oxidization of the metals becomes an issue. Just for the record 0.031″ diameter is fine for through-hole, but something like 0.020″ should be used for SMT work. 0.025″ is a decent compromise.

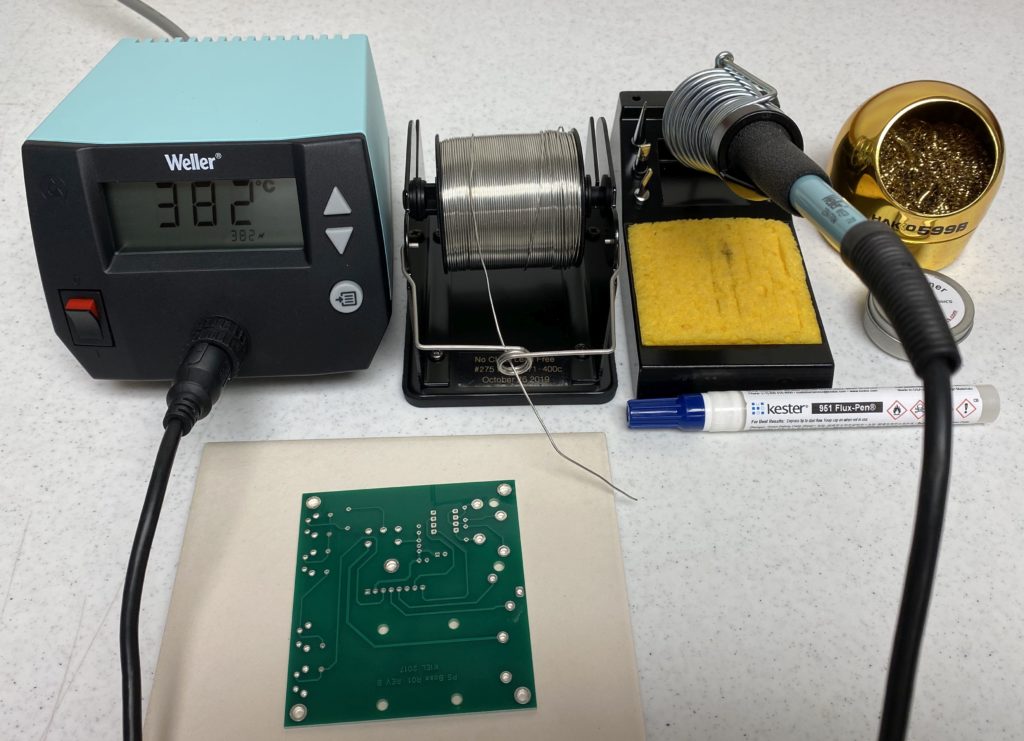

Soldering, especially now with lead-free, no-clean rosins, requires fairly modern tools that can achieve the correct temperature and maintain it despite the thermal load. Today that means an iron of 50 watts or more, and thermally controlled, with various tips to deal with through-hole or SMT devices. For decades (think mid 1980s), I have been using a workhorse Weller machine with thermal sensors built into the tips. It was accurate, but the temperature was either 700F /371C or 800F /427C, depending on the tip used. Current lead-free solder from Kester has a narrow temperature range of 371 to 400C. So the 700F tips were the bare minimum (and when cooling during the soldering process would drop too low), while the 800F tips were too hot, causing oxidizing issues.

So I decided to upgrade to a WE1010 Solder Station which has adjustable temperature settings — so it is easy to set it to 382C, pretty much ideal for lead-free/no-clean soldering (Like Kester 24-7068-7617 , lead-free no-clean #275 flux, with a diameter of 0.025″).

I found that the new solder station was about 40% less expensive through Amazon, but tips were about half the cost when purchased through an electrical distributor like Newark or Mouser.

So my old station is relegated to reworking older lead solder devices, while the new station will remain lead free for any new construction projects.