My KX3 fits in a small video camera bag, along with all the accessories (mike, paddle, PC cables, DC cord, spare batteries, solar charger, etc.), with room to spare. I wanted to add a light-weight antenna to make a complete pack.

I located a small Center Insulator with a BNC connector, called the MK-67 from www.ElectronicsUSA.com. By using BNC connectors, I’d have a direct match to my rig on one end and the antenna on another, and I could use light weight RG-174A/U coax for the feedline. I purchased a 25 foot pre-made cable from www.CablesOnDemand.com.

A nice thing about the MK-67 Center Insulator is that the antenna legs attach via wing-nuts. This naturally leads to making sets of dipole legs for the bands of interest. So you only need to purchase a single center insulator, but you can easily change over to any band you desire. In my case I made seven sets of dipole legs for all bands from 40 meters to 10 meters.

I used 22 AWG Silver Plated Teflon insulated wire that I obtained from eBay. Why Teflon? It resists kinking and the insulation is abrasion resistant. This makes it easier to deploy. I completed my antenna kit by obtaining hanks of Nite Ize Tent Cord. This cord is very strong yet thin and light weight, and it has a reflective weave that makes it stand out in the dark . Three lengths were obtained: one to hoist the center insulator up (although it can dangle in the middle if you don’t mind some sag), and one for each dipole leg.

The antenna legs were fabricated to be resonant toward the lower end of the ham band since I mostly work CW. An extra 1.5 inches was added to the formula length to make a loop in the end to affix to the support cord. So for 20 meters, I cut 16′ 6.5″. Color-coded heat shrink tubing protects the solder joint where the loop was formed, and helps keep the different sets of legs together. A closed ring-terminal was soldered to the other end of the wire.

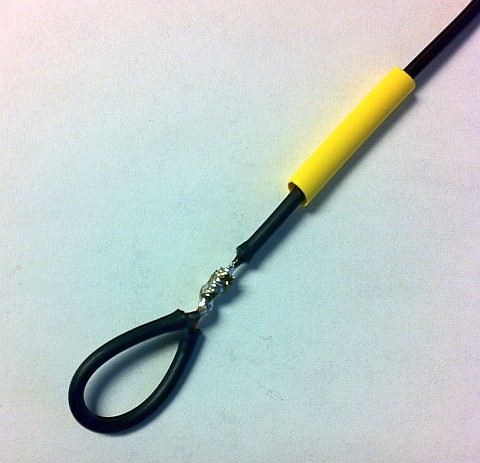

Basically after cutting the wire to the correct length (adding 1.5 inches for a loop), one end was prepared by stripping 0.75″ of insulation from the end. The insulation was then cut and partially stripped back about 0.25″, leaving about 0.50″ on uninsulated wire at the very end. A color coded piece of heat shrink is then slipped over the wire and the 0.50″ of bare wire is wrapped tightly around the exposed 0.25″ section, forming a 1.0 inch loop at the end) that looks like this:

After soldering the loop, the heat shrink tubing is slipped over the joint to cover the bare wire and heated to shrink in place. About 0.25″ of insulation is removed from the other end of the wire, and a ring-terminal is crimped in place. The terminal is then soldered for extra strength, and looks like this:

The entire 20 meter antenna package with coax, center insulator, and support cords weighs about 12 ounces and fits easily into my KX3 “GO Bag”.

Re: A 12 Ounce QRP Antenna

Posted on June 22, 2012 by robert

Is there any particular reason you picked teflon coated wire for your qrp antennas?

Thanks,

Dave

Hi Dave,

Mostly the reason is rugged insulation — I tend to toss the wire into trees and drag it over branches. Teflon is very rugged and resists kinking. I also try and find higher strand count, which improves the flexibility.

The down-side to teflon wire is it is harder to find and more expensive. So it may be better simply to use less expensive insulated wire and replace it more frequently.

73, Bob, WB4SON