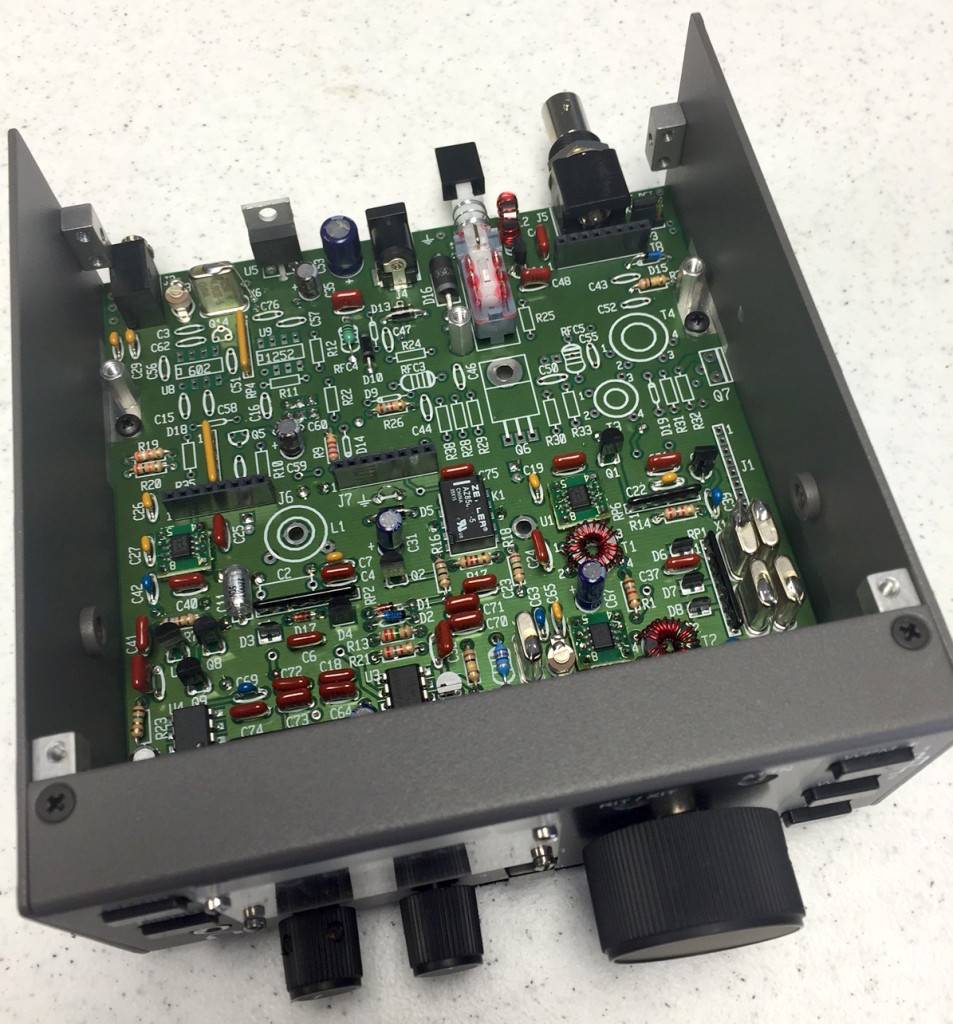

I spent 50 minutes installing mostly mechanical components to enable the initial K1 tests. In this final RX assembly part, a coax jumper was a major pain simply because it was short yet had to be lead formed to fit tiny holes on the PCB without having conductors fray. Pre-tinning them (I did that on one side) made the conductors hard to fit the holes.

The final reward was a series of fun tests. Audio hiss (with a pretty strange static crackling sound every 12 seconds or so — hope that isn’t a problem) came out of the headphones, the sidetone oscillator was adjusted for amplitude and frequency, and the keyer was tested. Relays clicked when bands were changed and the attenuator was exercised. So far all tests have gone smoothly, and only took 15 minutes to accomplish. This brings the total K1 Assembly and Test time to 21.7 hours.

The next major step is completing the VFO assembly which involves winding a toroid. At that point the full RX alignment can happen. TX assembly involves fabrication of 2 toroidal transformers and installing 55 resistors, capacitors, diodes, transistors, integrated circuits, chokes, plus mounting hardware for two power transformers. I’m going to guess 2 hours for the assembly and 1 hour for the alignment. So 25 hours seems like the final target.